| Products: |

Dry screw vacuum pump

Dry screw vacuum pump has the advantages of high operation efficiency, long life cycle, compact size and low maintenance charge. The dry screw pump adopts advanced German screw type line technology, and upgrade to improve combining with the characteristics of chemical pharmaceutical. With lower Exhaust temperature, high efficiency, Suitable for the gas suction containing flammable, explosive, corrosive, poisonous, and condensate. Possess the advantage of high safety, full closure and the characteristics of high efficiency energy saving.

Principle

The rotor of DH series dry screw vacuum pump is a pair of screw with small gap and no-contact. By synchronizing gear, drive toward the gas movement to the exit.

Technical features:

- The screw adopts Varying pitch contour line, and the compression and thermodynamic properties international advanced.

- Purity system with no oil and no water, totally closed working process, specially suits for the recycling of chemical gas medium, and can be applied for high purity vacuum process.

- High processing precision for the parts, all metal parts out of contact in operation, less wear, Dynamic characteristic optimization, long life.

- High precision dynamic balance, low vibration, low noise, high reliability

- Flow surface through special coating treatment, can take a corrosive gas and meet the needs of a special process

- Either as a single pump operation, also can be running as a backing pump

- Less parts, high stability, low maintenance cost, easy to operate

- Partition between continuous extraction, non-polar space block, short extraction path, avoid condensation gas condensation and corrosion pump cavity

- Compact type units, high automatic control level of integration, small occupation space

- Use the multiple seal, such as mechanical, maze and nitrogen sealing, implement closed transmission for flammable, poisonous and harmful gas

Technical index

| DH series | |||||

| Technical index | DH-160A | DH-250A | DH-400A | DH-630A | |

| Nominal pumping speed | m3/h | 132 | 216 | 350 | 630 |

| Ultimate pressure | Pa | ≤1 | ≤1 | ≤1 | ≤1 |

| Motor power | KW | 5.6 | 7.5 | 7.5 | 15 |

| Motor frequency | Hz | 50 | 50 | 50 | 50 |

| Rotating speed | rmp | 2950 | 2950 | 2950 | 2950 |

| Environment temperature | ℃ | 5-40 | 5-40 | 5-50 | 5-50 |

| Nitrogen flow | I/min | 6-10 | 6-10 | 2-3 | 5-7.5 |

| Cooling water flow | I/min | 5 | 5 | 6 | 6 |

| Noise | dB(A) | ﹤75 | ﹤75 | ﹤66 | ﹤75 |

| Air inlet flange connection | KF50 | ISO63 | ISO63 | ISO100 | |

| Air-vent flange connection | KF50 | KF50 | ISO40 | ISO40 | |

| Weight | Kg | 300 | 330 | 460 | 550 |

| Overall dimension | (L×W×H) | 1125×575×649 | 1190×575×649 | 1329×480×638 | 1500×522×689 |

| Explosion-proof grade | Ex d II BT4-Gb | Ex d II BT4-Gb | |||

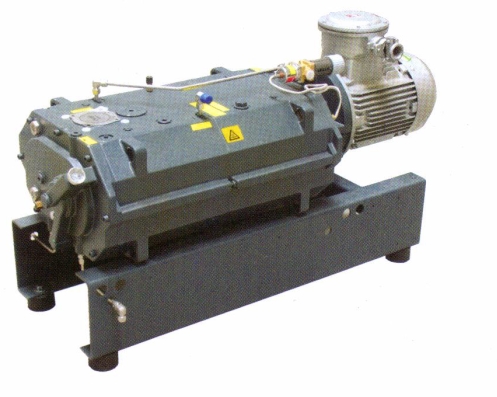

Installation sketch:

| DXH-250A, DXH-160A installation sketch | DXH-630A, DXH-400A installation sketch |

|

|

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

DXH-160A |

1125 |

181 |

100 |

542 |

309 |

100 |

575 |

130 |

295 |

198 |

DXH-250A |

1190 |

122 |

107 |

542 |

309 |

100 |

575 |

135 |

295 |

198 |

DXH-400A |

1329 |

777 |

372 |

1025 |

50 |

1154 |

355 |

480 |

592 |

638 |

DXH-630A |

1500 |

819 |

485 |

1100 |

100 |

1327 |

392 |

522 |

649 |

689 |

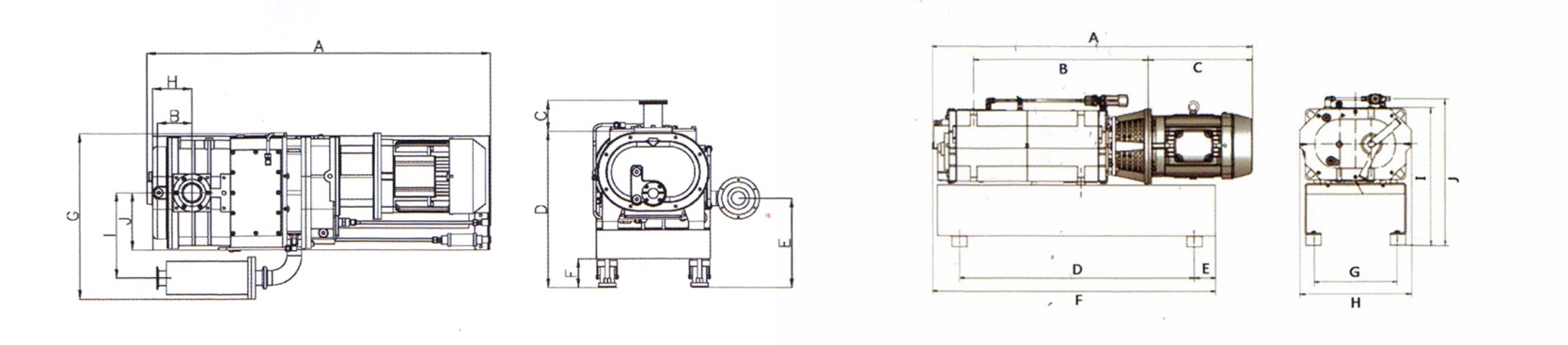

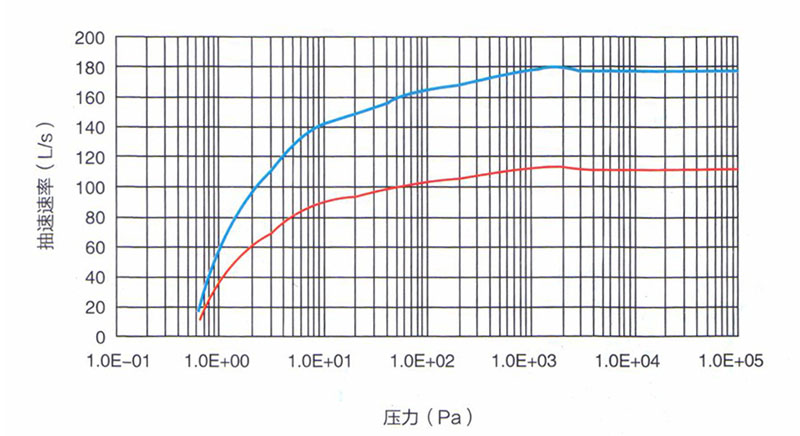

Pumping speed curve:

| DXH-250A and DXH-160A pumping speed curve | DXH-630A and DXH-400A pumping speed curve |

|

|

![]() Home >

Dry vacuum equipment >

Dry screw vacuum pump

Home >

Dry vacuum equipment >

Dry screw vacuum pump

DXT-450 Magnetron Sputtering System

DXT-450 Magnetron Sputtering System