| Products: |

sputtering vacuum ion pump

Product application areas:

Sputtering Vacuum ion pump is widely used in various kinds of ultra high vacuum of the scientific search and industrial equipment, mainly in the instrument, particle accelerators, synchrotron radiation light source, high power laser research, the surface of the logistics, materials science, space simulation, electron microscope, mass spectrometer, communications, vacuum calibration, vacuum metallurgy, vacuum coating, the application of semiconductor devices, vacuum electronics, medical and other industries.

sputtering vacuum ion pump

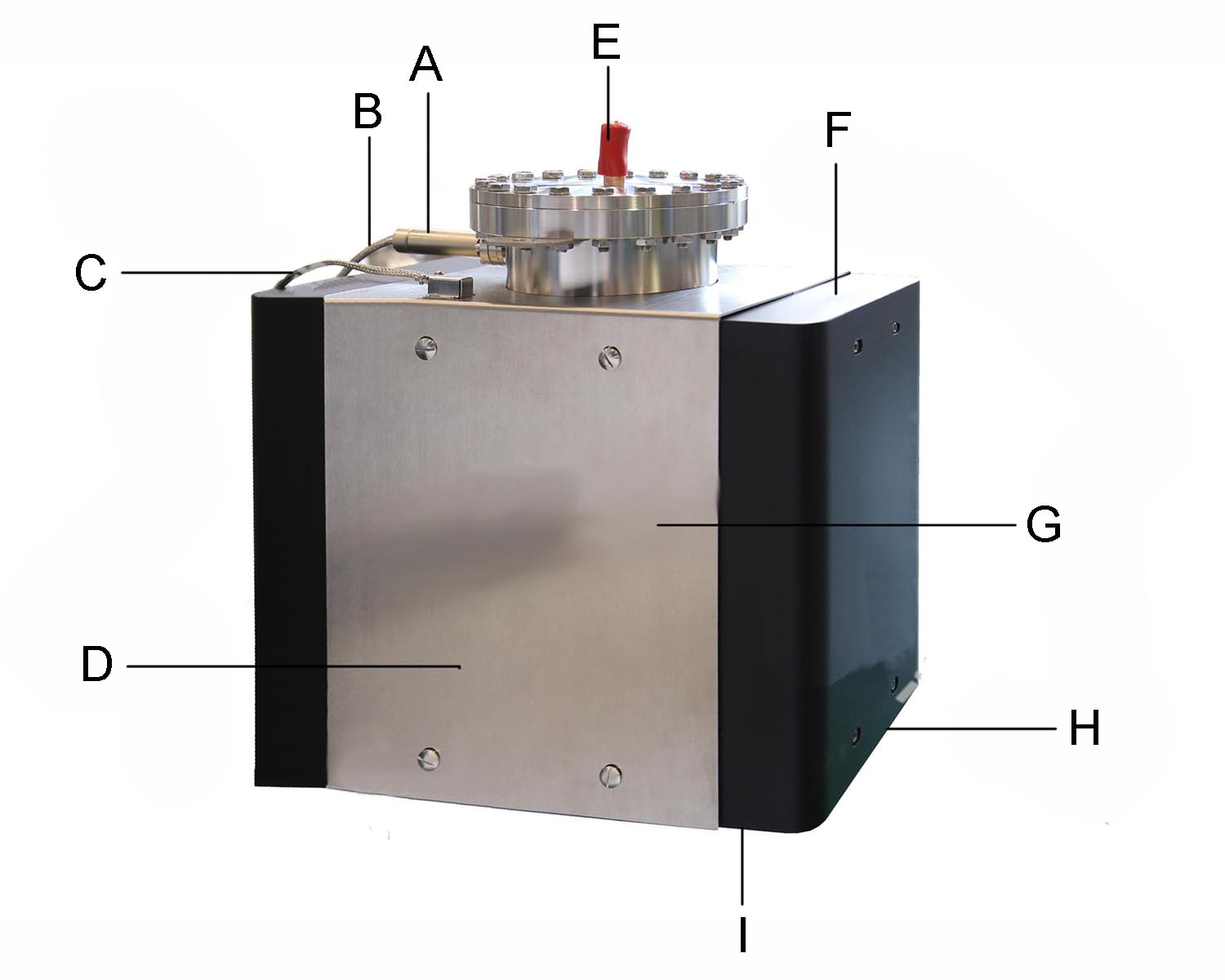

A. high pressure block

- The special design prevent of the rupture and leakage, extend the service life of pump.

- Equip with.interlocking device, disconnected without high voltage output, operating more safer.

B. Power cable

- High voltage safety interlock, outage automatic protection, running process more safer.

- The outer design of the Stainless steel, prevent electric leakage effectively.

- Custom appropriate length according to the customer’s requirements.

C. Baking equipment

- Adapt four piece heating plate stainless steel circular design, the roast is become more evenly

- The most economical operating costs lead to the roast more effectively.

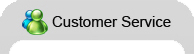

D. Anode tube

- Optimize the shape, dimension and alignment of the anode tube

It can improve the discharge rate and evacuation rate in the maximum scale.

Decrease dimension, reduce the weight.

- Adopt the 99 percent of the alumina ceramics

Insulation intensity up to the nA.level.

Reduce the accumulated of sputtering conductive coating.

Extend the service life of the ion pump.

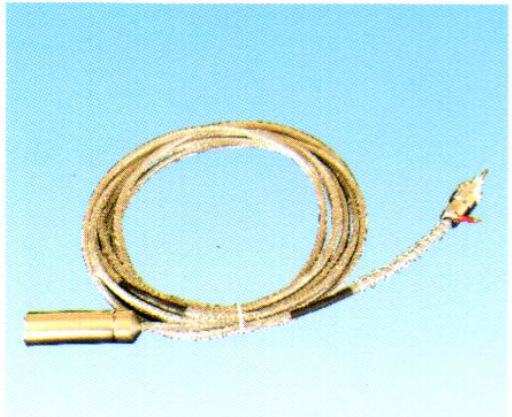

E. Degassing furnace

Sealing tube and the process of the manufacture

- The particular clean and high vacuum of the manufacture environment

- Using the high temperature and vacuum to remove the gas.

- The national standard of the testing instrument

- The more cleaner of the manufacturing technique.

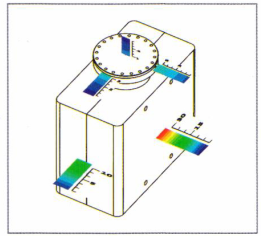

F. Pump body

Can custom made according to the customer’s requirements.

- The configuration of the pump can be made according to the customer’s demand.

The ion pump are custom made according the Composite getter (NEG)module

Titanium sublimation pump and low temperature cylinder.

Various kinds of connection port.

- According to customer’s currently condition, the same air pump can design into different shape or change the interface, make full of the space, which make the install more easier.

G. Air pump unit

- optimize the structure of air pump unit make the internal structure more conpactly.

- The ion flow discharge more stable upon the use of the high vacuum circumstance.

H. Pump case and coating

- The innovative structure design of the innovative,reduce the pump weight in the maximum scale.

- The whole pump adopt the special anticorrosive coating, make the ion pump can extract all kinds of corrosive gas, high temperature resistant, extend the service life of the pump under the bad environment.

I. Magnetic yoke

- Magnetic yoke select high permeability and high quality of the industrial pure iron to to improve the working efficiency of magnetic flux. It can prevent the leakage of stray magnetic fields.

![]() Home >

Sputtering ion pump >

sputtering vacuum ion pump

Home >

Sputtering ion pump >

sputtering vacuum ion pump

DXT-450 Magnetron Sputtering System

DXT-450 Magnetron Sputtering System