| Products: |

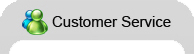

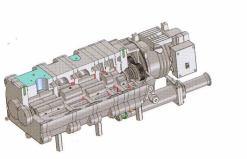

DXJM, DXJH series dry vacuum pump ( Unit )

| Multi-stage Roots pump | Claw type Roots composite structure |

|

|

Application fields

| Typical application process |

Cleaner process | Moderate corrosion process |

Strong corrosion process |

||||||||||||||||

| Pump type | Loadlock | Transfer | Metrology | Lithography | PVD process | PVD pre-Clean | RTA | Strip/Ashing | Oxide Etch | Silicon Etch | Metal Etch | Implant Source | HDP-CVD | RTP | SACVD | MOCVD | PECVD | LPCVD | ALD |

| DXM-100A | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| DXM-120A | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| DXJM-500A | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| DXJM-1000A | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| DXH-600A | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| DXJH-500A | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| DXJH-1000A | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

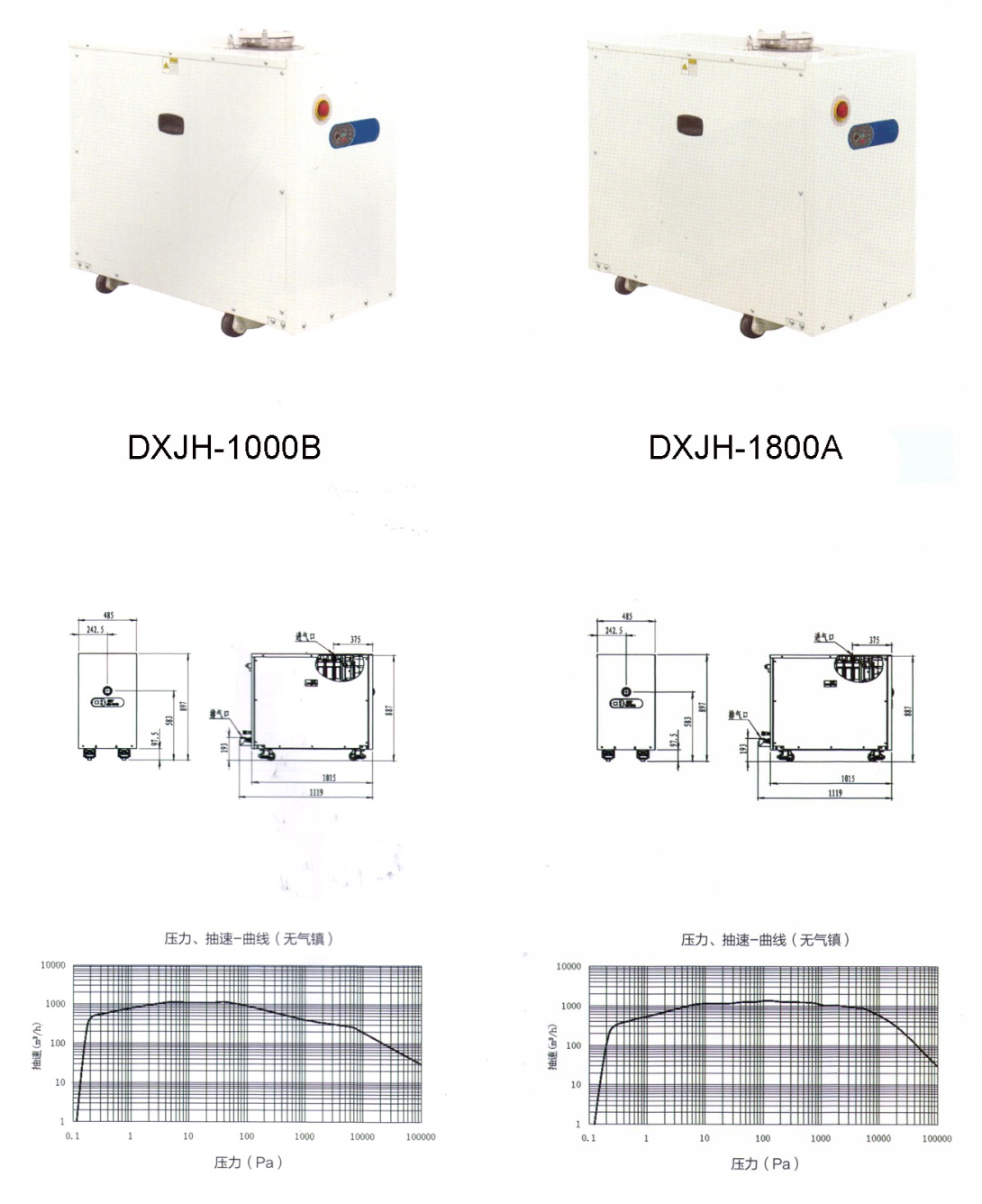

| DXJH-1000B | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| DXJH-1800A | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| DXJH-4200A | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

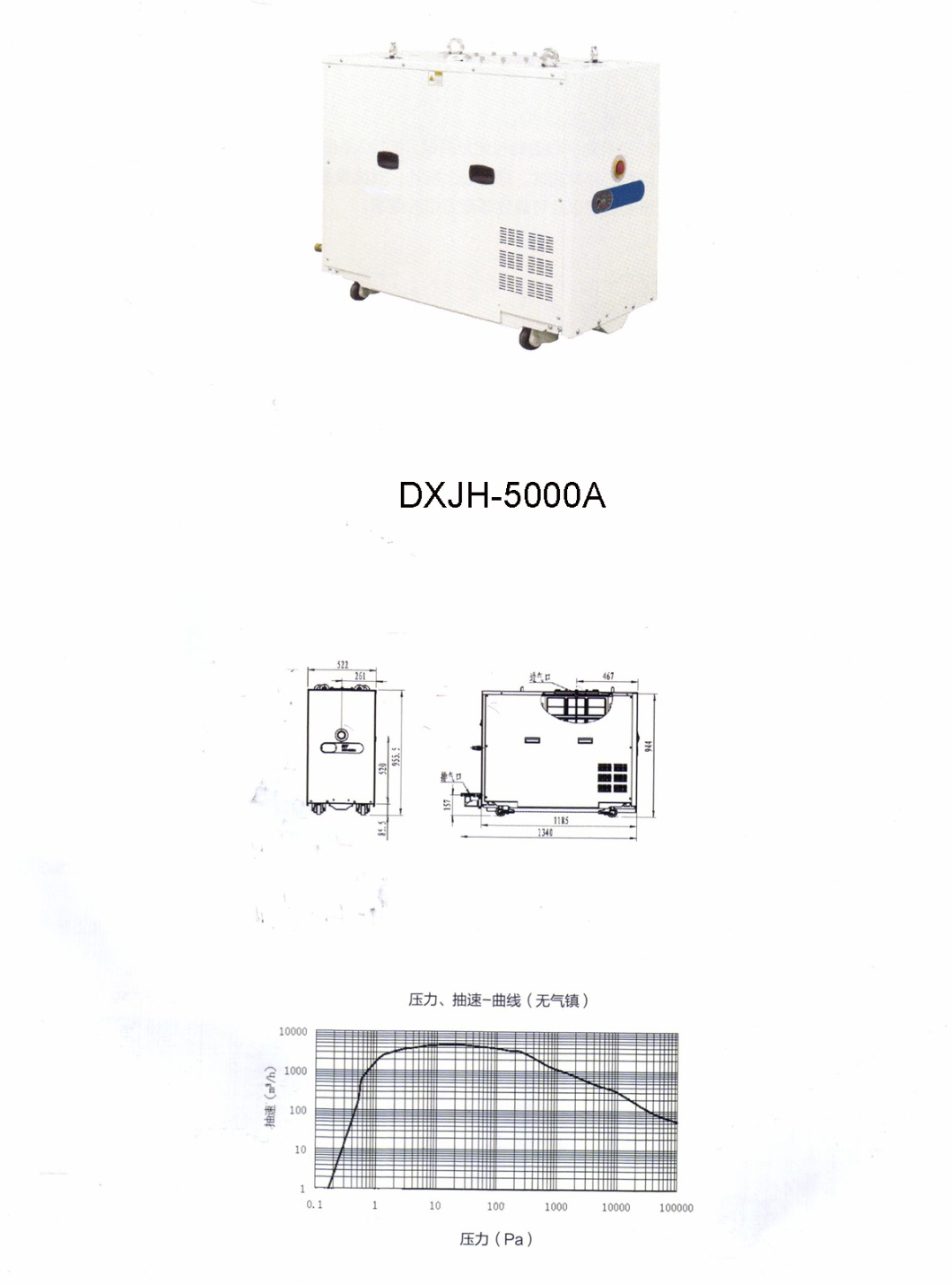

| DXJH-5000A | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

○: Available ●: Recommended use

Key application:

Integrated circuit、solar battery、LED field、available to loading cavity 、transmission cavity etc. cleaner process, and also available to PVD、etching、multiple CVD etc. moderate corrosion process or strong corrosion process.

Other application:

Vacuum melting (temper and anneal、steel degasification, surface treatment molten, refining, casting and welding, etc.

Vacuum coating system ( glass coating、precision optics, etc)

Vacuum packaging、food、chemical industry、medicine、 motor manufacturing industries distill、evaporation、drying, etc.

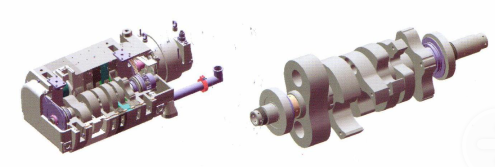

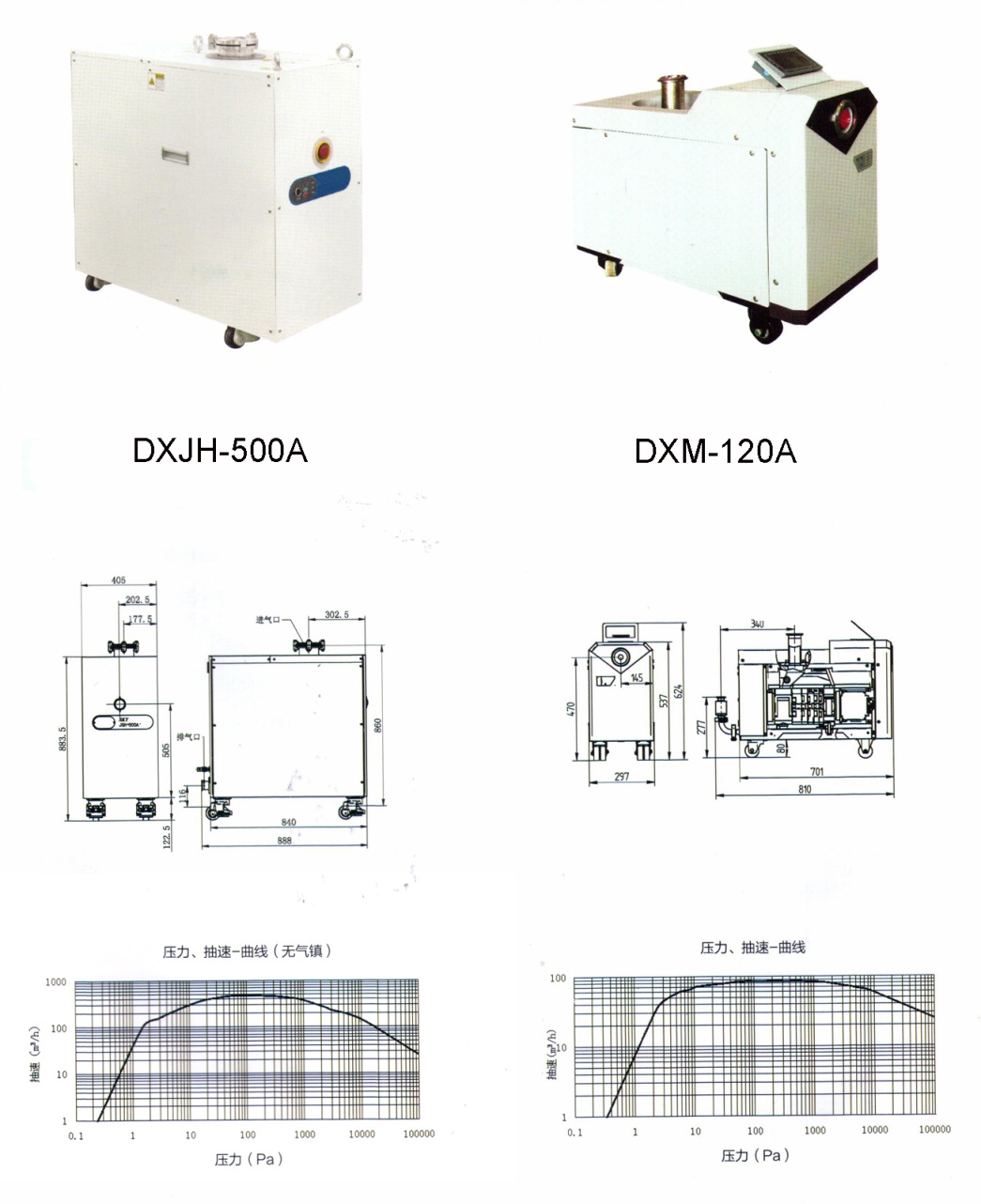

| Model | DXM-100A | DXJM-500A/ DXJH-500A |

DXM-120A | DXJM-1000A | DXJH-1000A | DXJH-1000B/ DXH-1800A |

DXH-600A | DXJH-4200A | DXJH-5000A |

| Pumping speed | 100m3/h | 480m3/h | 100m3/h | 800m3/h | 750m3/h | 1000/1400m3/h | 620m3/h | 3600m3/h | 4700 m3/h |

| Utimate pressure (Only the nitrogen purge of the shaft sealing system) |

10Pa | 2×10-1Pa | 5Pa | 2×10-1Pa | 2×10-1Pa | 2×10-1Pa | ≤10Pa | ≤5×10-1Pa | ≤5×10-1Pa |

| Power | Three-phase380 /208 50Hz |

Three -phase380 /208 50Hz |

Three-phase380 /208 50Hz |

Three -phase380 /208 50Hz |

Three -phase380 /208 50Hz |

Three -phase380 /208 50Hz |

Three -phase380 /208 50Hz |

Three -phase380 /208 50Hz |

Three -phase380 /208 50Hz |

| Motor rated power | 1.5KW | 3KW | 1.9KW | 3.8KW | 5.1KW | 5.8KW | 22KW | 33KW | 18.5KW |

| Rotate speed | 2865rpm | 2865rpm | 4600-5730rpm | 4600-5730rpm | 3420rpm | 3420rpm | 2865rpm | 2865rpm | 5730rpm |

| Environment temperature | 5~40℃ | 5~40℃ | 5~40℃ | 5~40℃ | 5~40℃ | 5~40℃ | 5~40℃ | 5~40℃ | 5~40℃ |

| Nitrogen flow | 0~60 slm | 0~60 slm/ 0-120 slm |

0~14 slm | 0~14 slm | 10~120 slm | 10~120 slm | 0~150 slm | 0~150 slm | 10~120 slm |

| Cooling Water Flow) | >1L/min | >1L/min | >1L/min | >2L/min | >4L/min | >4L/min | >4L/min | >8.5L/min | >10L/min |

| Maximum noise | <70dB | <70dB | <68dB | <68dB | <70dB | <70dB | <80dB | <80dB | <75dB |

| Air inlet flange connection | KF50 | ISO100 | KF50 | ISO100 | ISO100 | ISO100/ ISO160 |

ISO100 | ISO250 | ISO250 |

| Vent connection flange | KF40 | KF40 | KF25 | KF25 | KF40 | KF40 | ISO63 | ISO63 | KF40 |

| Overall dimensions | 830*390*530 (mm) |

1030*405*910 (mm) |

676*295*410 (mm) | 676*295*410 (mm) | 845*445*874 (mm) | 1079*485*894 (mm) |

1985*1107*1299 (mm) | 1985*1107*1810 (mm) | 1185*540*965 (mm) |

| Weight | 255Kg | 380Kg | 120Kg | 230Kg | 450Kg | 510Kg | 950Kg | 1700Kg | 890Kg |

JGH-1000B in the application of semiconductor devices

DXJM-500A in the production of PV production line

Optimize product performance, provide customized solutions

![]() Home >

Dry vacuum equipment >

DXJM, DXJH series dry vacuum pump ( Unit )

Home >

Dry vacuum equipment >

DXJM, DXJH series dry vacuum pump ( Unit )

DXT-450 Magnetron Sputtering System

DXT-450 Magnetron Sputtering System